This Ammo DIY Guide Will Help You Save a Lot of Money

Being prepared for an emergency scenario that may force you and your family to live in the wilderness takes a lot of effort and proper planning. Additionally, it requires extensive preparation to ensure that your family is ready to prepare a variety of handmade commodities needed daily but may be unavailable during an emergency.

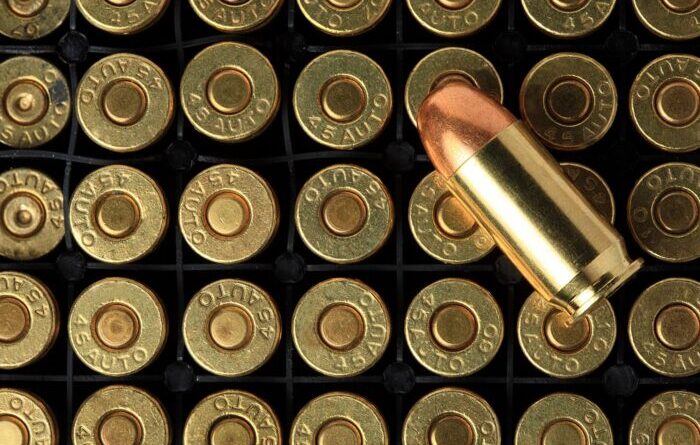

If you have a few firearms in your emergency storage, you almost certainly have a supply of bullets as well. However, if you need to survive in the woods for an extended time, your supply of bullets may run out. What happens then? Making homemade ammo is a crucial skill for any person who is familiar with firearms. If you want to experiment with loading bullets or shells into your shotgun or rifle, you will need some specialized materials and supplies. This ammo DIY guide is your best bet to help you make your bullets.

Things Needed for This Ammo DIY

Safety Equipment

Before you begin the exciting part, you must ensure that you have some essential safety equipment. After all, you will be dealing with hot stoves and liquid metal; thus, you must take all reasonable care to avoid burns and other accidents. To begin, you will need a set of safety glasses or goggles to protect your eyes from splashes. If you are melting a considerable amount of metal for the bullets, you will want to avoid getting it in your eyes or face. Additionally, wear thick gloves, as you will be working with boiling materials that will produce some pretty horrific scars if they come into contact with your exposed flesh. Wear leather gloves to protect your hands. Close-toed shoes are the last standard safety material. This is a relatively self-explanatory concept. If you are not comfortable with hot liquid metal getting on your hands, it goes the same with it getting on your feet. Apart from using protective gloves and eyewear, additional safety considerations include melting the metal in a very well-ventilated environment and constantly working on a solid surface.

Metal

Lead is the typical metal for ammunition production, but it is too soft for modern rifles and handguns, so you will need to combine it with a bit of tin to make it more rigid and easier to deal with. There are a few different sorts of shops where you can obtain your metal without paying for it for an arm and a leg. One of the reasons why people prefer to make their ammunition is that it is significantly less expensive than purchasing new rounds, so search around your local stores until you find the best deal if you do not want to make your ammo.

Typically, junkyards and plumbing supply stores sell lead. You can also find ammo-making supplies through mail-order companies or online retailers. However, the best place to find all of your metal is at an automotive and tire shop. The used wheel weights of cars are primarily composed of lead, tin, and antimony, which can help in increasing the bullets’ hardness and durability. They are essentially pre-combined bullets that have not yet been melted. The best part is that many of these establishments will offer them to you for a low price, or even free, and allow you to take as many as you like.

A Melting Pot

You may use a campfire and an old iron pot, and a spoon to melt all the lead alloy if you feel particularly cowboy-like. On the other hand, an aluminum pan and an electric burner will work just as well. Because your kitchen may not have the finest ventilation, a saucepan over a single electric burner is preferable to putting it over the stove. If you have a carport or maybe even a balcony, you can melt the metal there, as the combo of metal and wax needed in purifying the metal emits a tremendous amount of smoke. Together with the melting pot, having multiple stainless-steel condiment containers handy are a smart move. They resemble tiny buckets and are used to produce lead alloy ingots, which are then used to manufacture bullets.

The Flux

Fluxing the metal of a bullet is a critical step in manufacturing high-quality ammo. Flux is the term used to describe the wax or the bullet lube put into the molten metal to remove impurities and other debris. By adding a few flakes of wax or bullet lubricant, you can purify the lead alloy. It attracts all contaminants and metallic specks that are not tin, lead, or antimony.

Molds for Bullets

Bullet molds are available in an array of forms, sizes, and models. Each caliber, weight, and shape of a bullet requires a unique mold. These will need to be purchased through a company specializing in bullet manufacturing tools, which are typically available online.

The Process of This Ammo DIY Making

Once you have gathered all of the materials necessary to create bullets, it is time to begin. To start, you must set up your workstation in an outside area or in your garage. Ascertain that the location is adequately illuminated and ventilated. Begin by dissolving several kilos of wheel weights over an electric burner in an aluminum pan. Once the wax shavings or bullet lube have melted, you may begin the fluxing process by putting them in. The wax and lubricant may cause the melted metal to start smoking or even burn. This is normal; patiently wait for the smoke to cease before scooping everything off the top. Dump the skimmed contaminants into another small steel pan.

After obtaining a silvery-looking pot of melted lead alloy, gently pour the mixture into the stainless-steel condiment containers to produce ingots. Arrange the cups on a tray to create a flat surface. Additionally, you can place the baking tray on the ground to provide additional support. Using the pot, carefully put the melted alloy into the cups until they are about halfway full. When you are through pouring, allow the alloy in the condiment cups to harden. After approximately ten minutes, using your leather gloves, invert the condiment cups to let the newly produced ingot fall out. They should easily pop out, but if not, smack the bottom of the cup.

You now have an accurately shaped ingot and ready to be reheated and poured into the bullet mold. To make the ammo:

- Reheat the ingots and follow the steps indicated on the bullet mold.

- Pour the melted alloy into the bullet mold using a small iron ladle until a bit of puddle appears on top of the mold.

- Allow a few seconds before opening the mold and shaking the bullets out.

It is critical to wear safety goggles and gloves during this process to avoid splashing melted metal on your hands.

Do not forget that before following this ammo DIY guide, it demands that you have a thorough understanding of firearms and common sense. Working with any firearm is risky, and safety precautions must be taken at all times to protect yourself and others.